How to make a cone splitter with your own hands?

A DIY cone splitter will helpgreatly facilitate the process of preparing the material. For example, there are often problems with splitting wood at the moment of screwing in a screw or screw. This problem can be dealt with by pre-drilling a screw into the place of mechanical impact. The principle considered above is just characteristic of screw cone splitters. For greater efficiency, the cone was made with an increased diameter, while reducing the ratio of the thread depth and the tool diameter. In fact, the considered unit is a set of wedge and screw screws. The device easily enters the wood, tearing it through the fibers due to a significant increase in the working part introduced into the wood. Consider the features and characteristics of this device.

Varieties

Conical splitter with your own hands can be madein several variants. In the first model, the design provides for a screw that fits directly onto the shaft of the electric motor. In this case, rather strict requirements are imposed on the unit: the engine must have a low turnover (not higher than 500 rotations per minute), and also have a capacity of at least 3 kW.

In other configurations provideduse of electric motors of different types. The reduction in speed is achieved with the help of mechanical gearboxes, belt and chain type gears. A pulley with an asterisk of small diameter is mounted on the working shaft, and a star of increased diameter is mounted on the analogue of a drovokolny shaft. The approximate ratio is carried out in such a way that the design allows to reduce the frequency to 300-500 revolutions per minute. Sometimes efficiency is achieved without a significant increase in the size of the pulley, through the installation of an intermediate element and step transmission.

Benefits

Conical splitter with their own hands set on a solid frame, equipped with a folding table for easy operation.

The main advantages of the instrument in question:

- Simplicity of design.

- The ability to manufacture tools at home from scrap materials.

- High performance equipment.

- Low cost of mounting fixture.

- For the operation of the unit does not require additional training and special skills.

For the sake of justice, it is worth noting thatA hand-made cone splitter has a number of drawbacks. Firstly, such a tool cannot cope with interlacing fibers, as a result of which knots and some blocks have to be processed in a different way. Secondly, the mechanism cannot be properly manufactured without the use of a lathe. With all this, the advantages of the tool more than cover the existing shortcomings, and therefore the tool is very popular.

Requirements

Conical splitter with their own hands (photos, instructionsfor manufacturing are listed below) should ensure operational safety and high performance. To ensure the implementation of these parameters, it is necessary to adhere to the basic requirements and recommendations for manufacturing. Among them:

- The power of the electric motor should be in the range of 2-4 kW.

- To reduce the engine speed can be using a gear or flexible transmission.

- Compliance with the maximum frequency of rotation of the tapered shaft is not higher than 500 revolutions per minute.

- The tool must be equipped with a push-button switch, a magnetic starter and a safety (emergency) shutdown device.

- The tapered shaft is mounted on the bearing type.

- The cone must be equipped with a stop thread.

- If a belt drive is used, a pair of V-shaped belts and pulleys with two streams are used.

- During operation, the workpiece is supplied with their vertical orientation, which prevents skewing, jamming of the blocks and deformation of the installation.

How to make a cone splitter with your own hands?

The simplest design fixture thatthey offer some craftsmen, consists of a powerful perforator, with a tapered shaft clamped in a cartridge. Such a solution is very dangerous and has low efficiency. The fact is that it will not be easy to hold it while resisting wood fibers. If you decide to operate this design, take care to secure the device on a solid basis, which will allow you to use it in the traditional way.

To make a cone wood splitter with your own hands at 220 volts, you will need the following materials:

- Factory cone or its analogue, machined on a lathe.

- Shaft worker (in its quality, you can apply the hub of agricultural machinery).

- Pulleys and sprockets.

- The drive chain or belt from automobile or motorcycle vehicles.

- Bearings with housings, such as variations from automotive drive shafts.

- Profile pipes from steel (corners).

- Sheet metal for the work bench (thickness - at least 4 millimeters).

- Electrical engine.

- Wiring.

- Magnetic starter with switch.

- RCD.

- Bolts and nuts for fastening.

Features

Conical splitter with their own hands (photos, drawingsbelow) can be made from parts of used agricultural or automotive equipment. The most difficult in creation by element is considered the conical screw. With the help of the grinder, this node should not even try to build. Spent time and effort are not comparable with the final result, which will become a pitiful semblance of this screw. The analog made in this way will not even closely relate to the turning model in characteristics.

Preparation

In case of using the tool in the mobileform, you must first acquire metal wheels. Conical splitter do-it-yourself with a gasoline engine or diesel equivalent - the most optimal version of the mobile version.

Tools required for work:

- Welding machine.

- Drill with a set of drills.

- Saw-Bulgarian.

- A hammer.

- Spanners.

- Marker.

- Roulette.

To protect the product from corrosion, useany suitable enamel for outdoor use. Beforehand, it is necessary to carefully prepare the metal surface for painting by treating the area with a metal brush or a special emery nozzle on the “grinder”.

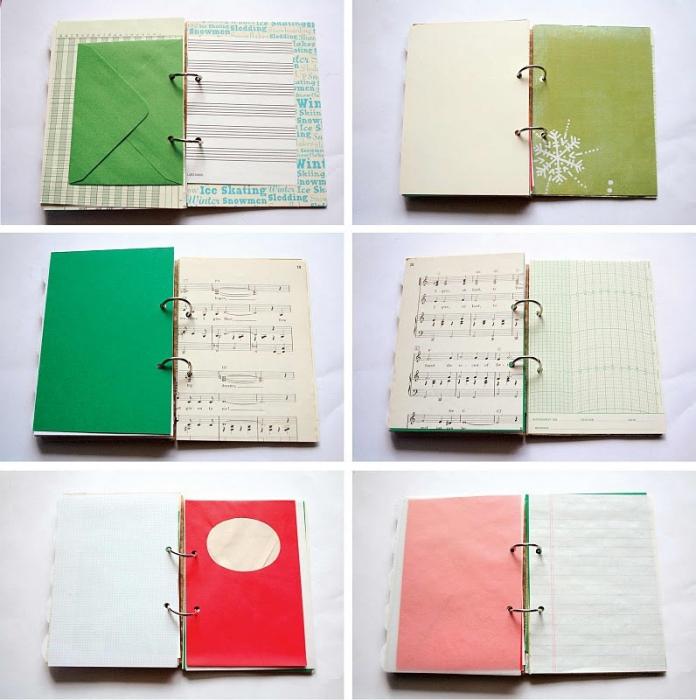

Conical splitter with their own hands: drawings, photos, instructions

Before undertaking the fabrication of a structure,it is necessary to create an elementary scheme that will allow you to outline the main dimensions of the machine and related elements. You will also need a sketch of electrical wiring and connections. The diagram below presents the basic principle of operation of the machine.

Since the most important detail in the designis a wedge, its manufacture should be discussed in more detail. Best of all, the part is made of tool steel. For the processing of this material will require a true professional, because the steel has high strength characteristics, it is difficult to process. Most often, the screw is made from the brand St-45. This requires reinforcement of the threaded compartment by quenching, nitriding, or cementation.

Dimensions

Conical splitter with their own hands (drawings, photosabove) will work efficiently and for a long time only if the cone is made correctly. The order must specify that the turning of the workpiece is required in the parameters of ½ with a hard pair of thread 5-6 mm. Standard metric thread in this case is not suitable, it is much worse than cutting into wood. The dimensions of the screw wedge and the size of the taper are directly related to the marginal size of the split.

Approximate dimensions of the bed are shown below:

- Length - about 850 mm.

- Width - 600 or 1000 mm (with folding table).

- Height - up to 800 mm.

Finally

Usually a lower arrangement is used.electric motor. This solution makes it possible to protect the working parts of the engine from chips and debris. If the engine is used as a motor, it is mounted on the same level as the wedge. This configuration is more convenient during the start-up of the unit, and also allows you to adjust the speed and refueling during operation.

Working with a screw splinter should be respected.extra care. The process is dangerous in that the momentum is gaining a high moment on the edge of the element. In this regard, it is necessary to stick the block of wood with bare hands in order to avoid winding fabrics from gloves or long sleeves. You should also protect the machine from excessive moisture and temperature extremes.